BUILDING ICONIC 1950’s PORSCHE DREAM MACHINES!

Jason Ferraro, founder of Renner Automotive based in a cosy warehouse conversion in an inner eastern suburb of Melbourne is now applying his 30 years of experience and skill building the iconic 356 Speedsters. Jason initially built a beautiful Ford GT40 replica and has now set about recreating 21st Century 356 Speedsters with innovative high-tech chassis, high-powered, water-cooled, fuel injected, turbocharged engines and sophisticated drivetrain systems.

The first four Renner Auto 356 Speedsters have now hit the road having gone through the rigorous ADRs, approved engineering certificates, road tested and fully legally registered for everyday road use.

The genesis of these modern-day 356 Speedsters begins right here in Melbourne, Australia! Chassis, engines, and all components come through Jason’s front door with Jason and his small team taking on the assembly work. These classic 1956 Porsche 356A Speedster recreations have all the high-tech mechanical and electronic systems incorporated along with the wonderful ‘creature comforts’ every modern-day sports car has to offer including heated seats, air conditioning and blue-tooth technology. Ferraro holds Australian manufacturers in very high regard and is installing PWR radiators and turbo charger intercoolers in each of his cars along with Melbourne manufacturer Davies Craig supplying Thermatic Fans, the EWP115 Electric Water Pump and EBP40 Electric Booster Pump and advises: “PWR and Davies Craig are both tremendous partners in our Speedster recreations and are among the many excellent local suppliers we use.”

“We commenced the Speedster development project two years ago and all first four of these vehicles have been delivered to clients,” he says. “Components for the next four Speedsters are well on the way to completion and we plan to produce a further eight each year.

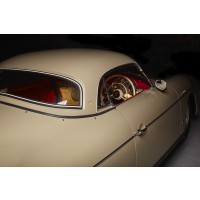

“Although we modelled and designed our vehicles to closely resemble the original item, we sell them as a Renner Auto Speedster. You can’t recreate a vehicle from scratch and name it a Porsche, and it can’t leave our workshop with Porsche badges. We can however carry out a ground-up restoration on a Porsche and this car can clearly retain all the iconic Porsche markings, badges etc, as a restored vehicle. We had an original Porsche 356 Coupe in the workshop, which we are completely modernising internally, and therefore this vehicle retained all its Porsche classic emblems.”

“Original classic Porsche Speedsters are continuing to appreciate in market value and can sell for upwards of A$700,000.

Ferraro speaks with great enthusiasm for his business: “Renner Auto is celebrating the high point of automotive design, the period between 1950 and 1965, through the building of new cars that pay tribute to that period’s styling. These vehicles possess the styling that make them an instantly recognisable classic. By using advanced manufacturing, we build a modern chassis, engine and electrical system that makes them as advanced in technology and up to date as new vehicles.”

Ferraro adds, “I purchased the 3D printer two years ago. We 3D print prototype and select production parts using this equipment, and it has enabled us to implement OEM (original equipment manufacturer) solutions at volumes that were not previously viable. As well as the 3D printing and supporting CAD design work, I do a lot of general workshop operations, such as TIG/MIG welding and composite work.”

Dream machines - How it works at Renner: most clients are local and after scheduling an appointment, they’ll come into the workshop for a site visit. Ferraro says that some clients have even ordered their vehicle build on the spot. Several of Renner’s custom vehicle projects have seen clients investing over one million dollars to create their dream vehicle.

Ferraro uses a wall display of 3D-printed Speedster models for clients to choose the vehicle’s external colour and upholstery.

“I provide an estimated price and time frame to the client, and we often run on an open book costing model.” says Ferraro. “We use 3D scanning equipment to digitise the vehicle structure and then commence the 3D CAD design of all the vehicle systems. Then we install the modern internal components in the body, so that it resembles the original vehicle with a high-tech engine and a modern internal operating system.

The recreation of a classic vehicle takes up to 2,500 hours to build and there are usually up to six cars being built at a time. Significant time is spent on vehicle R&D and fit-out.

“Clients are involved during the build both via Zoom, regular newsletters and now face to face, post COVID-19 lockdown. They get very excited, like we do, when their custom-built vehicle is nearing completion.”

We have also completed the other metal assemblies that make up the cars and they have already been e-coated and zinc yellow plated. Every component is correctly coated so there are a few!

Written by John Benson of Davies Craig with the kind permission of Jason Ferraro www.rennerauto.com.au